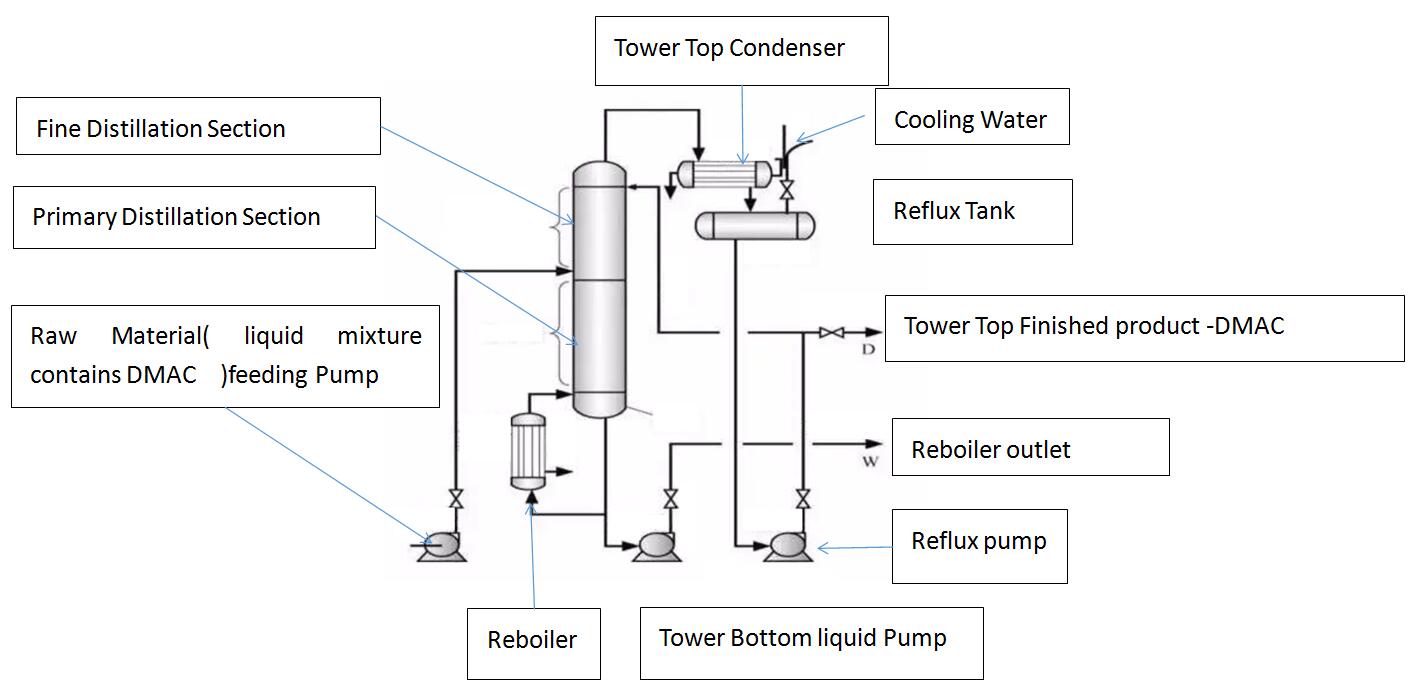

Overview of DMAC distillation tower

Wuxi Hongdinghua Chemical Equipment Co., Ltd. (HDH) focuses on the design and manufacturing of distillation towers for various applications. DMAC distillation towers are also a type of distillation tower commonly designed and manufactured. Due to the close physical and chemical properties of DMAC and DMF, DMAC has better performance compared to DMF. As an industrial solvent, DMAC is also used by many manufacturers in the industrial field. The DMAC distillation tower is also selected by customers using solvents to achieve its recycling, reduce pollution, and reduce production costs.

When designing and manufacturing DMAC distillation columns, it is also necessary to have a in depth understanding of the physical and chemical properties of DMAC, as well as a understanding and rich experience in the operation and maintenance of DMAC distillation columns. Wuxi Hongdinghua Chemical Equipment Co., Ltd. (HDH) is a professional manufacturer from Wuxi, China, with both technical capabilities and rich manufacturing experience. HDH will provide you with DMAC distillation towers with excellent cost-effectiveness, stable operating performance, efficient processing capacity, and convenient maintenance

DMAC scientific name is Dimethylacetamide, with the molecular formula CH3CON (CH3) 2. Dimethylacetamide can dissolve various compounds and is completely miscible with water, ether, ketone, ester, etc. It has the characteristics of high thermal stability, low hydrolysis, low corrosion, and low toxicity, and is widely used.

HDH has a professional technical team and HDH will provide the DMAC distillation tower technical solution you need based on the technical parameters you provide. Due to different conditions, the DMAC distillation Tower (columns) designed and manufactured by HDH for customers are inevitably different. Therefore, please provide the following data to HDH so that HDH can provide you with a technical solution as soon as possible.

Parameter provision

Parameters (specifications): Each tower is custom designed and manufactured based on the following parameters (specifications). HDH requires you to provide the following data:

(1) Raw Material Feeding amount per unit time: _____

(2) Detailed composition of raw materials: _____

(3) Tower top output amount _____kg/h, with a concentration requirement of _____%;

(4) Tower bottom output amount _____kg/h, with a concentration requirement of _____%;

(5) Whether the material has thermal sensitivity: _□_;Please specify: _____

(6) Corrosion: _____;

(7) Operating flexibility: _____upper limit; _____ Lower limit;

(8) Operating time: _____ hours/day;

(9) Cooling water temperature (inlet/outlet): _____℃ in summer, _____℃ in winter;

(10) Chilled water temperature (inlet/outlet): _____℃;

(11) Steam pressure (gauge pressure): _____MPa

(12) Heat transfer oil temperature: _____℃;

(13) Installation environment: indoor □; outdoor□

(14) Meteorological environmental conditions

(15) Selection conditions for electrical equipment (Electric Power Supply Condition) _____

Performance and application of DMAC distillation tower

DMAC Distillation Tower is used in resin, especially in polyurethane resin, polyimide resin production enterprises, heat-resistant synthetic fiber enterprises, plastic film, coating, medicine, acrylonitrile spinning enterprises, many foreign production polyimide film, soluble polyimide, polyimide polyfluoroethylene propylene composite film, polyimide (aluminum) film Soluble polyimide molding powder enterprises and domestic enterprises producing polymer synthetic fiber spinning and other organic compounds. These enterprises all require DMAC distillation towers.

Detail of DMAC distillation tower

General DMAC distillation tower is very similar to DMF distillation tower in it’s structure designed